by Dr E. Ramanathan

Generally, thickness of different types of phosphate coating is reported as coating weight. Weight per unit surface area of phosphate coatings is calculated as follows. The coated specimen is weighted to the nearest mg (w1); the coating is removed by immersing the coated specimen in a 50 g/L chromic acid stripping solution at 165oC for 15 minutes; then the specimen is cleaned in running water, dried and reweighted (w2); this procedure is repeated until a constant weight is obtained.

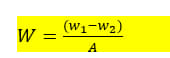

Coating weight in g/m2, given by

The iridescent blue amorphous iron phosphate layer has the coating weight between 30 and 100 mg/ft2. Spray type phosphate coating forms coating weight of 100 to 400 mg/ft2, medium hot immersion zinc phosphate coating forms 450 to 1000 mg/ft2 and heavy zinc phosphate coating forms 1000 to 3000 mg/ft2. Manganese phosphate coating weight ranges from 1000 to 3000 mg/ft2. Heavy zinc phosphate coating and manganese phosphate coating exhibit lot of pores on their thick layer deposited on the metal. Though they are not suitable for painting due to their more porous and rough surface, the heavy phosphate treated metal surface is ideal for oiling, waxing and lubrication and hence such type of heavy phosphating is employed on the metal components where painting is not required. The cathodic and anodic phosphate coating on mild steel components have been reported to improve the adhesion of paints applied on the metal [10].