Learn Paint Technology in your mother tongue (Tamil, Hindi, Malayalam, Kannada, Telugu)

Select your language

https://wa.me/p/8299162933441716/919444929163

One Year Course Offered by Saitech Informatics under the guidance of Dr E. Ramanathan Surface Coating Consultant with Telegram Chat Support for further training and consultations.

Course Fees Details:

Monthly Subscription: Rs. 3000

Annual Subscription: Rs 33,000

Payment Mode: GPay 9444929163

Unlock The Secret Formulations in Coatings

Emulsion Paints | Solvent Based Paints | Metal Pretreatment chemicals | Nano Coatings

Introduction about Diploma in Paint Technology

Surface Preparation

- Introduction

- The need for metal surface treatment

- Different types of metal pre-treatment

- Corrosion theory.

- Coating weight and thickness

- Selection of suitable chemical conversion coating

- Phosphate coatings

- Nano-ceramic Coating

- Surface preparation of metal panels for corrosion studies

- Surface preparation of wood and cement slab for antifouling studies

Paint Applications

- Paint applications techniques

- Different Types of Paints

- Coating Defects and trouble shooting.

- Painting specification and inspection.

- Testing and calculation while painting- viscosity, sp.gr, covering etc.

- Application safety. – Safety at height, safety in confined place etc.

- DFT measurements and area measurements

- Pollution control, Effluent Treatments

- Paint Brushes

- Spray Guns and Spray Booth

- Heating Ovens

Paint Formulation Guidelines

How to formulate a paint – A general idea

A) Water Based Paints for Civil Works

B) Air drying enamels and primers

C) Stoving Enamels

D) Wood Finishes – Sanding sealer, wood primer, air drying varnish, Quick drying clear, PU clear coat

E) Metal Pretreatment Chemicals – Degreasing, Derusting, Phosphating, Passivation, Nanocoatings etc.

E) Epoxy Paints

F) Polyurethane Paints

G) Metallic Finishes

H) Quick Drying Acrylic Finishes

I) Metallic Paints

Raw Materials Section

- Pigments

- Extenders

- Resins

- Solvents

- Additives

Machinery

- Stirrors

- Ball Mills

- Attritors

- Mixing tanks

- Moden Equipments

- Filling Machines

- Labelling Machines

Laboratory Equipments and Glassware

- Laboratory Glassware

- Laboratory accessories

- Testing Instruments and Equipments

- Standard Manuals

- Shade cards

Metal Finishing

- Basic Electrochemistry for Electroplaters

- Acid pickling, degreasing and passivation

- Chrome plating

- Zinc plating

- Electroless chroming

- PVD Coating

References

Recently updated articles

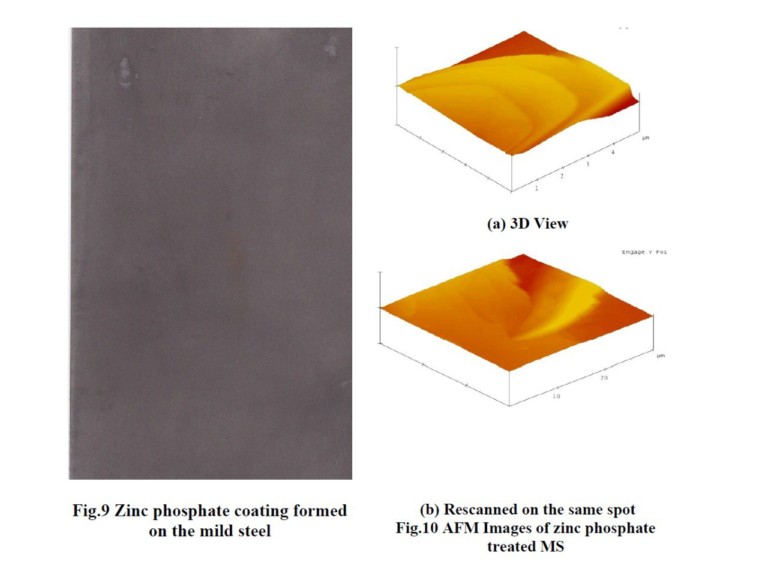

Phosphating Chemicals

Phosphating Chemical Formulations Metal Pretreatment Chemical Case Study Videos Phosphating Formulations https://www.youtube.com/live/Rw9MuLmR_G4?si=3kK0YBFfVip6sGEc Metal Pretreatment Chemical Case Study https://www.youtube.com/live/D6HR7pgoHwM?si=WUo5pv2jcnfpskOB

Wall Paints

How to make wall paints? How to make paint generallly? – தமிழில் Emulsion paints How to make emulsion paints? Cleaning exterior wall and interior wall before painting Acrylic emulsion paint formulation guidelines – class-1 , class-2 Videos How to make wall paints? https://youtu.be/JmJG0OEVzUw?si=XTynNSAlyLYU_JVw How to make paint generally? https://youtu.be/tGAHZPw96ng?si=BMzldcvfAqFUdp2R சுவருக்கான பெயிண்ட் தயாரிக்கும் முறை https://youtu.be/ouucszO__lw?si=geyfJ0ydD_AzjXLI Emulsion…

Heat Resistant Silver Ash Paint

Nitrocellulose and acrylic resin based paint Non-leafing metallic aluminum Quick drying acrylic resin Moderately heat resistant Metallic finish Ideal for metal components, automotive parts Formulation Guidelines Raw MaterialsQty, kgNon-leafing aluminiuim paste40Quick drying acrylic resin330N/C solution66.6Butyl acetate50Ethyl cellosolve or butyl cellosolve20 Procedure Stirror mixing Room temperature Application Spray type Air drying Suitable for metallic components Automobile…

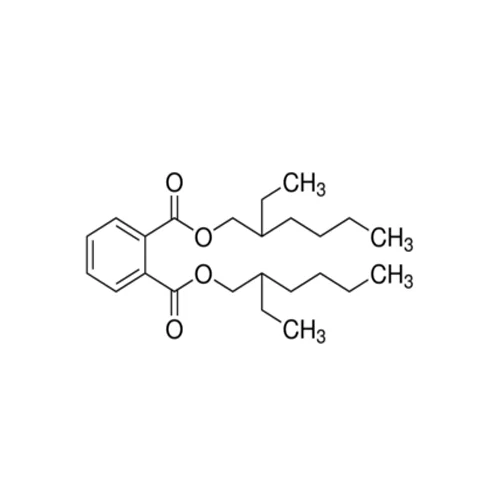

Plasticizers

Plasticizers: Definition: Plasticizers are additives used to increase the plasticity or fluidity of a material. They are commonly incorporated into polymers to make them softer, more flexible, and easier to handle. Function: Plasticizers work by embedding themselves between the chains of polymers, spacing them apart and thus increasing their mobility. This process reduces intermolecular forces…

Surfactants

Surfactants, or surface-active agents, are compounds that lower the surface tension between two liquids, between a gas and a liquid, or between a liquid and a solid. They contain both hydrophobic (water-repellent) and hydrophilic (water-attracting) groups, allowing them to interact with both water and oils or fats. Types of Surfactants: Nonionics: No charge in their…

Sustainable Coaching and Sustainable Coatings

Article by Dr E. Ramanathan When we talk about quality of a product or a service from client’s perspective, we bluntly believe branded products or services, fake advertisments in social media, TV shows, newspapers, movies, magazines, etc. We assume falsely that anything Global is great in quality. We just think big about big advertisements and…

Continue Reading Sustainable Coaching and Sustainable Coatings