by Dr E. Ramanathan PhD

Monthly Subscription Fees for Nanocoatings update: INR 6,000. You will get various formulation guidelines in nanocoatings, testing methods, trouble shooting, manufacturing details, suppliers details, machinery details, packing guidelines, etc.

Subscriptions can be paid by any of the following methods.

- Direct Payment through Gpay 9444929163

- Payment using our payment portal https://saitechinfo.com/stores/product/nanocoatings/

Here is a detailed list of topics typically covered when studying or discussing nanocoatings:

1. Introduction to Nanocoatings

- Definition and importance of nanocoatings.

- Historical development and advancements.

- Basic principles of nanotechnology relevant to coatings.

2. Types of Nanocoatings

- Hydrophobic and superhydrophobic coatings.

- Hydrophilic and superhydrophilic coatings.

- Anti-corrosion coatings.

- Anti-scratch and wear-resistant coatings.

- Thermal barrier coatings.

- Self-cleaning coatings.

- Anti-fouling and anti-microbial coatings.

- Anti-reflective coatings.

- Conductive and electro-conductive coatings.

- UV-resistant coatings.

- Optical coatings.

3. Materials Used in Nanocoatings

- Nanoparticles: TiO₂, SiO₂, ZnO, Al₂O₃, Ag, Au.

- Polymers and hybrid materials.

- Carbon-based nanomaterials: graphene, carbon nanotubes.

- Ceramic and metallic nanomaterials.

4. Fabrication Techniques

- Sol-gel method.

- Chemical vapor deposition (CVD).

- Physical vapor deposition (PVD).

- Spray coating.

- Electrospinning.

- Dip-coating.

- Layer-by-layer assembly.

5. Surface Properties

- Wettability: hydrophobicity and hydrophilicity.

- Mechanical properties: hardness, adhesion, scratch resistance.

- Optical properties: transparency, anti-glare.

- Thermal properties: insulation and resistance.

6. Functional Mechanisms

- Self-cleaning effect (Lotus Effect).

- Anti-microbial mechanisms (ion release, contact killing).

- Anti-corrosion mechanisms (passivation, barrier formation).

- Conductivity enhancement.

7. Characterization Techniques

- Surface morphology analysis (SEM, AFM).

- Coating thickness measurement (ellipsometry).

- Water contact angle measurement.

- Adhesion tests.

- Scratch resistance testing.

- Corrosion resistance testing (electrochemical techniques).

- Thermal conductivity analysis.

8. Applications of Nanocoatings

- Automotive industry.

- Aerospace and defense.

- Construction materials.

- Electronics and semiconductors.

- Healthcare and medical devices.

- Renewable energy (solar panels, wind turbines).

- Textile and leather industry.

- Marine and shipping.

9. Advantages and Challenges

- Benefits of nanocoatings (durability, multifunctionality).

- Cost and scalability challenges.

- Environmental and health concerns related to nanoparticles.

- Regulatory considerations.

10. Emerging Trends and Future Perspectives

- Smart nanocoatings (responsive to environmental stimuli).

- Bio-inspired and biomimetic coatings.

- Nano-enabled green coatings.

- Applications in advanced manufacturing (3D printing).

- Integration with IoT and sensors.

Trication phosphating chemical

Trication phosphating formulation guidelines

Protected: Nanoceramic Coatings – Synthesis, Characterization & Applications

Synthesis and Characterisation of Nanoceramic Coatings. Book authored by Dr E. Ramanathan PhD

Continue Reading Protected: Nanoceramic Coatings – Synthesis, Characterization & Applications

Nanoceramic Coating an Introduction

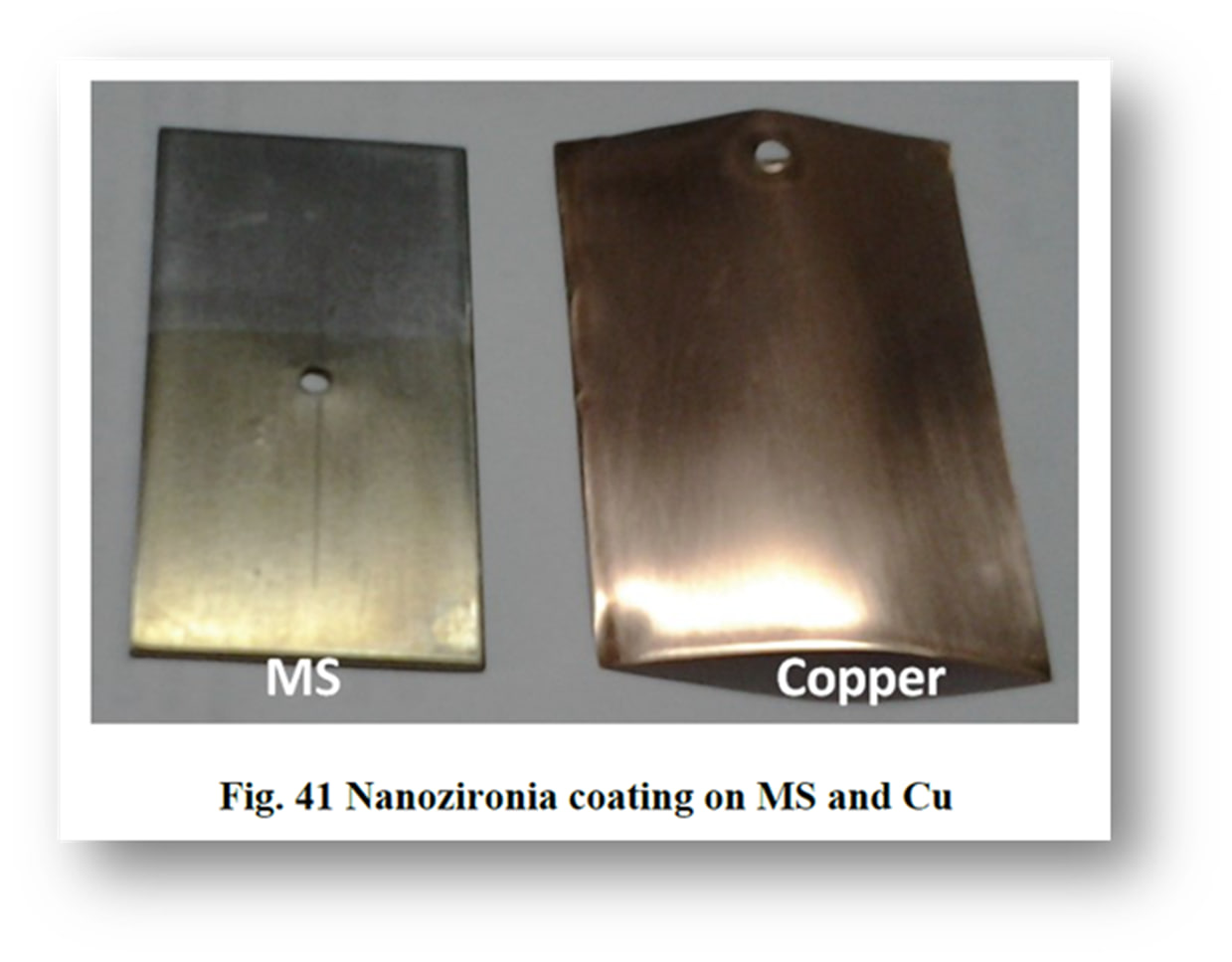

Advantages of Nanoceramic Coating over Zinc phosphate coating – Zinc Phosphate Coating has been widely used in metal pretreatment for more than five decades. Limitations of traditional zinc phosphate coating: High energy and power consumption; excessive sludge formation, posing disposal issues; prolonged processing time, especially for room-temperature phosphate coatings. Zirconia, titania, ceria, and zinc oxide coatings have been researched for superior corrosion resistance. Nano-coatings do not form insoluble sludge, making them eco-friendly alternatives. No heavy metals such as chromium, nickel, or manganese are involved. Applications in Marine and Industrial Sectors: Nano-ceramic coatings help in preventing microbial colonization and fouling in marine environments and in improving durability in industrial applications.

Nanoceramic Coatings

by Dr E. Ramanathan PhD Nanoceramic coating presentation by dr eramanathDownload

What is Nanocoating?

Nanocoatings are ultra-thin layers, typically measured in nanometers, that are applied to surfaces to enhance their properties. They utilize nanotechnology to modify the surface characteristics of materials, providing a wide range of functional benefits. Types of Nanocoatings: Anti-Corrosion Coatings: Protect metal surfaces from oxidation and corrosion. Commonly used in automotive, aerospace, and industrial applications. Self-Cleaning…

COVID-19, Is it a virus or nanoparticle?

Highlights: • Nanoparticles • Nanotoxicity • Covid-19 Virus vs NPs • Nanotherapeutics https://youtu.be/Rex9x4hjOZk •Nanometer = 10-9 m •1 Angstrom =0.1 nm •Diameter of Hydrogen atom = 0.1 nm •Diameter of COVID-19 Virus = 100 nm •Solute and Solvent •Adsorbate and adsorbent •Solvation, Coagulation, Clotting • •High surface are to volume ratio •Morphology •Controllable aggregation •Size…